Below is our list of tips for using pneumatic tube systems to gather accurate and useful information on unsealed roads, dirt tracks and areas subject to flooding.

1. Take extra care when securing tubes to gravel

Nailing or screwing tube sensors into unsealed roads can be problematic due to the soft nature of gravel/dirt. We recommend using 200mm Deck spikes to secure tubes properly and avoid loosening over time. Deck spikes are much longer than road nails, allowing deeper penetration into softer road surfaces.

Using 100mm bugle (hex drive), head coach screws with washers may also work. These have the low head profile of road nails but are threaded for strength of purchase.

Make sure deck spikes or screws are installed into a section of compacted road, far from any edges, potholes, or crumbling areas.

2. Protect your tubes from punctures

Due to the rough surface of an unsealed road and the weight of passing vehicles, rubber tubes can wear out very quickly or suffer punctures. To avoid constantly replacing the tubes, try some of these methods:

- Sweep any debris and larger stones from the area around the tubes.

- Place a rubber mat or timber base under the tubes.

- Feed tubes through lay flat hose (see below).

A popular way to ensure the durability of tubes is to feed them through a length of small-diameter lay flat hose before installation.

Lay flat hose is normally used to transport giant volumes of liquids like water or oil (think a fireman’s hose). They are made of reinforced, braided material that is extremely durable but still allows for rubber tubes to record changes in pressure caused by a vehicle’s wheel.

Visit your local fire brigade to recycle decommissioned lay flat hoses for free. Alternatively, you can buy lay flat hoses in various sizes online.

Unsealed cycleway surveys don’t tend to suffer as much from tube wear out due to the lighter nature of bikes and scooters. Lay flat hoses aren’t required when using the RidePod® BT; however, we suggest checking tube sensors weekly for any potential punctures.

“We monitor cyclists permanently on the Wadden Islands. In this case, with rubber tube sensors because it wasn’t possible to install piezoelectric strips. 2 years after installation and everything is still in good shape”. – Robert Mulder, Survey Manager in the Netherlands.

3. Check sensors regularly from your desk

Even when applying the above methods we recommend checking survey sites at least weekly to ensure tubes are still secured, in good condition and not losing tension. This will avoid data gaps and potentially having to resurvey.

If your sites are located far from the office/depot or are difficult to access, you can check the condition of tubes, diagnose potential issues and download data from your desk using the Remote Access Link.

The Link securely transmits information across a mobile network. To ensure it will work for you, test your mobile coverage at ground level wherever you intend to install a Link with your traffic counter. If you can make a call while lying on the ground, you’re good to go!

4. Communicate with road graders

To avoid tube sensors being ripped off the road by graders, make sure they are informed of current traffic surveys or organise for counters and tube sensors to be removed in time for grading.

If grading hasn’t occurred and you notice ruts appearing under the tubes, or they are floating in a tyre groove, this may not actually be a problem.

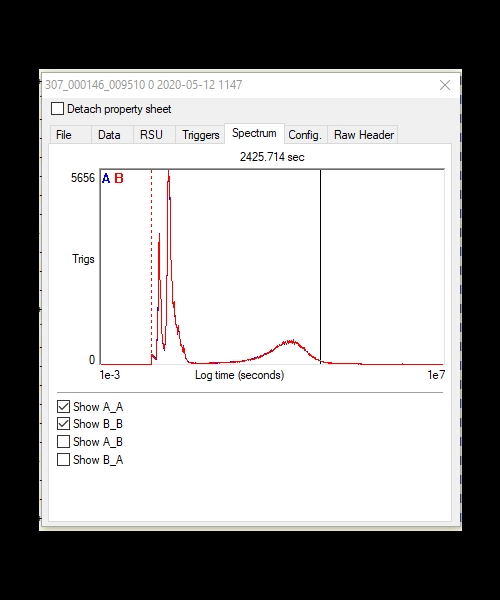

Check your sensor balance using the Triggers and Spectrum tabs in MTE® software and you may find that your counter is continuing to detect axles accurately despite the tubes being suspended.

After identifying floating tubes on a gravel road in Gnowangerup, WA Technical Officer David Barker checked the survey's data quality and confirmed that the sensor balance was not adversely affected (as seen on the left).

“Although having suspended tubes, the RSU is most likely registering each strike correctly,” David Barker.

If this is not the case and you notice a sensor imbalance, you may need to infill the ruts and tyre grooves or check other potential causes of problematic data collection.

Concreting or adding bitumen/asphalt to a small section of road around a survey may be a good option for long-term projects.

5. Elevate tube ends on floodways

All MetroCount traffic counters leave our Western Australian factory fully weatherproof.

Although they have been used to monitor traffic on floodways and in areas prone to inundation, we recommend avoiding placing counters where they are likely to get flooded (as water may enter the housing if the counter is old or has had a battery change).

Water can also be sucked up the end of tube sensors and cause data quality issues during your survey.

To ensure you get the best data try elevating the tube ends off the road or knotting and securing them so that the tube ends face upwards.

If you'd like more information on the best way to monitor traffic in unique situations, give us a call or comment below, and we'll be happy to share our knowledge.

The above tips and techniques are those that our clients have found useful when surveying traffic on dirt roads. You must apply your best judgment on whether you'll proceed with an installation at any location or use the above tips. MetroCount is not liable for any loss or damage resulting from traffic survey installations.

Got a great MetroCount story? Share it with us and let the world know the great work you're doing in your community.